I°ĘGeneral Description

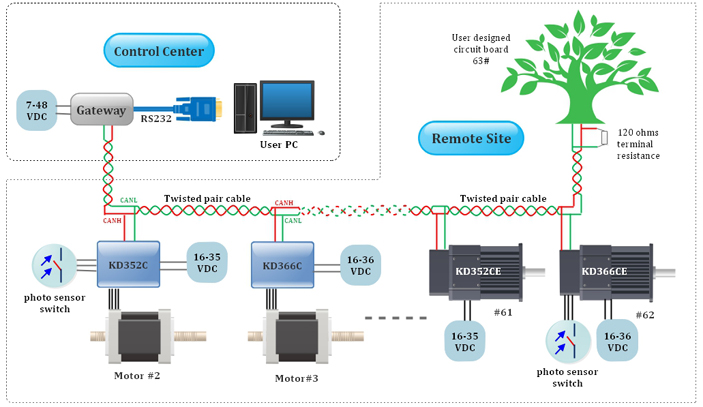

CAN bus step motor driver series launched by KDE fetures brief instruction and smart control.The system is comosed of one gateway and a number of drivers connected by CAN bus in series.Flexiable expansibility,good anti-interference,long communication distance,compact size,make it ideal for step motor control applications.Both rising edge and falling edge signals of the four sensor ports can trigger configured reverse direction ,moving forward a number of steps.All working parameters can be setted and stored in internal ROM permenently.

48VDC 8A version is available.

II°ĘSpecifications

| Model | Supply Voltage | Output Current | Current Resolution | Maximum Subdivision | Configurable Thermal Shut-down Range | Out Voltage for Sensor | Requirement on Sensor Signal Edge | Complient electric level of Sensor Ports |

| (VDC) | (A) | (A) | (°ś) | (V) | ||||

| KD352C | 12-35 | 0.1-2 | 0.1 | 16 | 50-120 | 5 | <50us | TTL |

| KD352CE | 12-35 | 0.1-2 | 0.1 | 16 | 50-120 | 5 | <50us | TTL |

| KD366C | 12-36 | 0.1-6 | 0.1 | 256 | 50-120 | 5 | <50us | TTL |

| KD366CE | 12-36 | 0.1-6 | 0.1 | 256 | 50-120 | 5 | <50us | TTL |

III°ĘAdvantages

| Intelligent |

The amount of steps required for acceleration and deceleration is certain,which saves user from complex calculations especially in debugging stage.

|

| Accurate |

Avoid flaw of bad step record resulted from OS task switch or interuption seen in similar kind of drivers from other company.

|

| Enough Ports |

Two sensor power supply ports design simplifies cable connection and can meet most needs.

|

| Protection |

Thresholds of thermal warning and shut-down are configurable and noticeable.

|

| Open Protocol |

Easy to and circuit boards designed by user as nodes to the system.

|

| Superior cool Standby |

Benefitting from creative technology in KD366 series,switch power consumption in coils is reduced more than 85% theoretically compared to traditional drivers in standby mode while keeping same level hold torque.

|

| Excellent torque curve |

KD366 series drivers do have remarkable linear speed-torque curve and perform excellently even at the speed of 720 RPM.

|

| EMC |

Good EMC design.

|

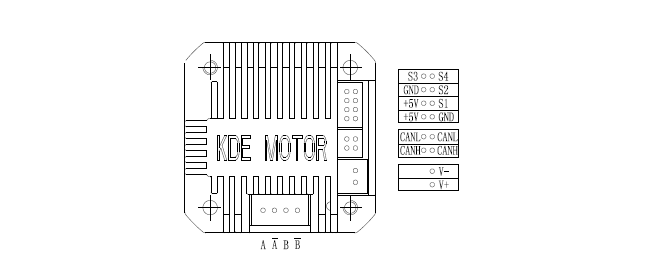

IV°ĘApplication Connection Diagram

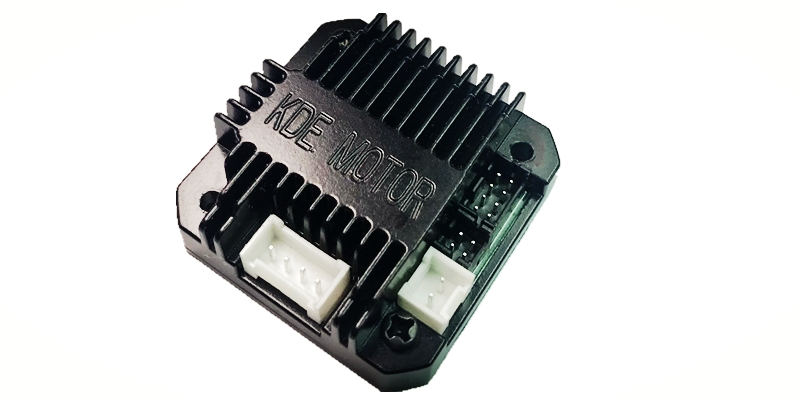

V°ĘMechanical Dimensions

VI°ĘWiring Diagram: